Testing the Water Master Fire Pump

It's been a long time since I've made an actual post, although the blog information is updated frequently. There are various reasons for this, especially that I'm the only one who does posting, and I have other fish to fry too. And there are quite a few things to catch up on, and I hope to do so in the near future.

But this might be of interest to those who, like us, want to test the fire pump on a Water Master tanker. I did a lot of internet searching on the subject without success, although I did locate the current Water Master supplier, but we purchased ours in 2005 and the fire pump was added separately, which I understand is no longer the case. So for those who are in our situation, this might be helpful.

A few weeks ago we'd taken the pumper and the Water Master tanker up to a lake near Winterville to get them pump tested. You have to do this on an annual basis for satisfying insurance requirements for the class we're trying to achieve. The pumper did ok, but the Water Master tanker couldn't be tested. The guys doing the testing spent a couple of hours at it, but couldn't figure out how to draft and pump simultaneously, so that had to be put on hold.

The reason you have to draft (suck water out of a pond or lake) and discharge at the same time is that you have to maintain 1000 gallons per minute discharge for twenty minutes, so you need a larger body of water as your reservoir. The guys knew how to do the pumpers, because they're common and well known.

I tried to describe to them how I thought it could be done with the tanker, but they were reluctant to try it. In their defense there was a secondary issue that made them reluctant to proceed further. The manufacturers of the fire pump had neglected to include a test specification plate with all the pump info, so they couldn't assure themselves of what the pumping capacity was and were skeptical of our recollection that it was 1000 gal/min (it is). They don't want to burn out someone's fire pump, so that ended it.

Fire Chief Ed did have an indirect conversation through one of the test guys to the company that makes the Water Master tankers. I'm giving the third hand report, but the upshot was that simultaneous discharge and drafting (sucking water out of the lake) couldn't be done.

That just didn't seem right to me, so I devised a procedure for doing it, and last night we tested it out and it worked just fine.

Here is how we normally use the tanker (called a tender in the West - tanker is used to describe a plane or helicopter dropping water or other suppressant from the air).

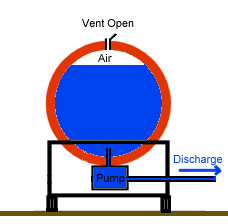

| The tanker is a modified septic tank sucker, with a big sealed 2500 gallon tank shown in red, sitting atop the truck. The fire pump pumps water out of the truck. There's a vent that you can open or close from a big panel with lots of switches and LEDs sitting between the driver and passenger seats. For the normal operation you keep the vent open, of course, for you do not want to develop a vacuum in the tank as water is pumped out of it. |

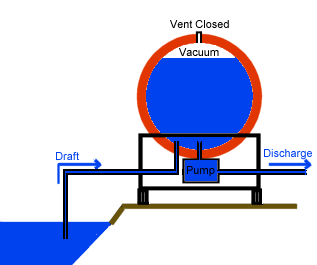

| Here is how we needed to operate the tanker. It's the same figure from above except that we also needed to pull water into the tank while we discharged. The main concern here was for pump testing, but in general we'd also need to do this for nursing other trucks when hydrants aren't present. In most parts of Oglethorpe County, hydrants aren't present, but there are little ponds and lakes around. |  |

The big difference is that now we operate the fire pump with the vent *closed*, something you "never" do. As the fire pump pumps water out of the tank, a vacuum forms. This vacuum pulls water out of the lake to replace the water that has been removed from the tank.

And that's what we demonstrated last night. Very simple. We dumped water from the pumper into a drop tank to serve as our "lake." From the tanker in the second figure above, we put our 6" suction hose. We hooked up our discharge to the pumper, and turned the fire pump on. And it filled the pumper while immediately beginning a suction from the drop tank, just as predicted.

Once the pumper was full again, we hooked up the deck gun and repeated the process, discharging into the air, until we'd emptied the drop tank first, and then the tanker at 400 gal/min, keeping the rpm's low just in case there was a problem. Worked fine!

Now, in defense of the assertions that we couldn't accomplish the intended goal, I'll have to introduce a complication. The Water Master has a *second* pump, a vacuum pump, that is normally used to fill the truck from a lake on a one-time basis. With the vent closed, you turn the vacuum pump on, it removes the air from the tank, and the water comes in to replace it. Simple! That's how the ancestors of this truck clean out septic tanks, only there it isn't simply water that is sucked into the tank.

So I think the testing guys, who knew something about the tanker, and the manufacturer guys too, were fixated on using the vacuum pump and the fire pump at the same time to accomplish our needs, and their conclusion was that it couldn't be done. Maybe they were also blindsided a bit by the rule that you never use a fire pump with the tank vent closed. And to do what we did means you had to violate that rule.

We still haven't fully tested it, since to achieve the 1000 gal/min we'll have to rev up the fire pump rpm's at least 2.5 times higher than we tested it out at. But that's what the fire pump is built to do. So I can't see why that would be problem, unless the fire pump is doing a double duty that decreases its ability to discharge. And that's why we need a test spec plate, so we know the maximum rpm's we can safely operate it at, as well as the gallons per minute it's expected to deliver under normal conditions.

To repeat: that's also why we need to get that test plate, hint hint.

I really wish I'd taken my camera - it was pretty impressive when we were pulling water out of the drop tank into the tanker, discharging it into the pumper, and then using the pumper's fire pump to return it back into the drop tank. We had a full circuit of water moving, with the physics of gravity and atmospheric pressure completing a critical portion of that loop.